Customer Help Centre

Frequently Asked Questions

Click or tap a question listed below to expand for an answer.

Pre-Purchase

Getting Started

Flue Questions

Fireplace Questions

Customer Help Centre

Pre-Purchase FAQs

Click or tap a question listed below to expand for an answer.

What is Pyroclassic Fires' return policy

Pyro Fires is committed to customer satisfaction. If you are unhappy with your purchase for any reason, return it to our Hastings factory within 30 days in the condition and packaging you received it and we will happily refund your money.

Please note: A 20% repackaging and restocking fee applies.

What type of flue do you recommend?

We recommend a 150mm flue kit for your Pyro Fire.

As we are a carboNZero certified organisation, we are not keen to support the unnecessary freight of bulky flue components great distances when there are comparable products available from reputable manufacturers in your locality. Please speak to your local Pyro agent about the Flue Kit options available to you in your area.

What are the clearances for a Pyro Classic installed on a mini raised woodbin?

You can download the installation clearances for installing a Pyro Classic (Pyroclassic IV) on a mini raised woodbin HERE.

How does the Pyro Classic burn overnight?

The overnight burn ability of the Pyro Classic (Pyroclassic IV) is 100% dependent on the quality and size of fuel you put in it.

You will need to have a good ember bed established, then add 2 or 3 dry hardwood logs (preferably Kanuka) measuring approximately 400mm long by 120mm thick into the fire box. Allow the flames to establish on the front ends of the logs and then ensure the turboslide is fully closed meaning the air flow into the fire is controlled by the fire itself. The further back in the fire chamber you have the fire the longer it will burn for.

Remember, you need to add a kilo of fuel for every hour burn time required. If you follow these instructions you should have some hot embers left in the back of the fire chamber in the morning ready to be brought forward to establish another fire.

As a point of caution you should never insert a fresh log which is too large or placed in the fire too late to ensure a flaming combustion, doing this will cook the wood fuel on the remaining embers releasing unburnt volatile gases into the combustion chamber which will eventually reach a point of ignition, this can result in a sizable explosion inside the fire chamber and may cause damage to the unit.

Can I install a second hand wood burner?

We recommend you discuss your plan to install a second-hand woodburner with your local city or district council or the unitary authority in your area before purchasing the woodburner. There are factors in addition to the National Environmental Standards for Air Quality that these agencies need to consider before permitting the installation of a second-hand woodburner.

See more information at http://www.mfe.govt.nz/air/national-environmental-standards-air-quality

Can I use a heat transfer kit?

The simple answer is yes.

The thing with heat transfer kits is they work well with excess heat. The Pyroclassic IV produces a different kind of heat than your traditional ‘black box’ style wood fire. The black box fires spit out heat almost instantly as long as you keep refueling it regularly so will therefore provide you with excess heat which is why heat transfer kits are useful for these kind of fires. The Pyro on the other hand takes longer to heat up but once up to temperature retains this heat like a kiln and gives off a lovely, warm more consistent heat with less fuel needed once the cylindrical ceramic fire chamber is hot.

Many Pyro customers find this as the biggest advantage of a Pyro and have it going for 2-3 months solid during winter. However, it won’t necessarily provide lots of excess heat for use in a transfer system. Our recommendation is to install the Pyro first before the transfer system as you may likely find you don’t require one.

It is worth noting that in newer homes which have much better seals around doors and windows these kits can cause a negative pressure to build up in the room the fire is in as all the air is being sucked out. This results in the fire being starved of air and in some cases has even caused smoke from the starving fire being drawn back into the room. This same effect can also be caused by powerful range hoods and other fan forced systems in newer, more airtight housing.

If you are building a very airtight home, we recommend you put in an air vent, approximately the size of a fire brick. The Pyro Classic (Pyroclassic IV) needs 3.6 cubic metres of air per kilogram of wood to operate effectively.

Why is the door glass small?

Big door glass = big waste of heat

Glass is a very poor insulator, which is not ideal when it comes to wood fires!

The original Pyroclassic fire did not even have a glass as the scientists wanted the fire to be as efficient as possible. Over time, consumers expressed their desire for a window into the fire which has resulted in the glass getting larger with each version.

The Pyroclassic IV has the largest door glass that can be fitted to the front of the fire as the glass retaining strips fit just inside the front opening of the fire chamber.

Why have Pyroclassic Fires dropped from No. 1 on Consumer NZ tests on their last report?

Consumer Magazine recently changed the way fires are rated. This has caused some issues across the industry as what were considered the ‘best’ fires are now not rated near the top…like the Pyroclassic IV. They have changed the weightings of their review to focus more on price for output over emissions and efficiency as they believe this is more in line with what the customer wants.

This has resulted in a list which is more about heat output for dollars spent rather than which fires actually perform the best. It also makes no provision for servicing costs, warranty duration or expected life of the appliance and its components.

The statement we have printed in our marketing material – ‘Consistently chosen as the top pick for wood fires in all Consumer reviews’ refers to the consumer reviews across various formats in NZ, Australia and the UK over the last 30 plus years including true consumer feedback.

Can you configure the flue to have an offset so it goes out the wall behind the fire rather than the roof?

Yes, offset bends are available for the flue systems. The best option would be to speak with a local installer who can give you specific advice about a flue system to suit your home.

Do note that a general rule of thumb is to try and avoid having any offsets in the first length of flue pipe, no more than a 45 degree angle and no more than 600mm centre to centre of the offset. Offsets do require more maintenance with cleaning etc. and can have adverse effects on the fires performance versus a typical vertical flue.

Can I cook on the top?

Yes you can cook on the 10mm thick steel top plate of the fire once a good fire has been established inside the fire chamber. You can use this area for all manner of cooking or warming. The cooktop oven provides better control and more versatility with cooking, which can be purchased from our online shop.

Cook top area measures 0.26m2.

Why do I need a Wall Screen or a Flue Shield?

Pyroclassic Fires can be installed with a double skin half round flue shield or for minimum clearances from combustible walls a correctly sized wall screen must be installed, the clearances for these are shown in the relevant Tech Spec sheet for each fire.

Alternatively you can install a Pyroclassic Fire without wall screens if you chose to use a non-combustible wall board product such as Eterpan, Supalux or Promina board and install it as per the manufacture specifications. Usually this involves ensuring a 25mm air gap is maintained between the wall board and any timber framing, through the bottom, up between the combustible surface and the screening material and out of the top.

In some instances the wall may not contain any combustible material and therefore will not require any screening.

Pyroclassic Wall Screens now have a simple keyhole hanging system to make installation very easy.

Who should I use to install the fire?

As a responsible manufacturer we recommend that all our fires are installed by a New Zealand Home Heating Association approved installer. This will ensure the fire is installed correctly and safely and will provide many years of worry free comfort.

How much does it cost?

To download the RRP price list of our Pyroclassic wood fire and accessories, click HERE.

What if I have a two storey house and require extra flue lengths?

A longer flue is fine however this will cause the fire to run at a slightly higher burn rate and consume more fuel than usual due to the extra draw that this length puts on the fire, otherwise there is no issue with this.

Download our second storey penetration kit installation instructions HERE.

What is the warranty for Pyroclassic parts?

The ceramic firebox in the Pyroclassic IV is warranted for 15 years against defective material or workmanship, providing that the fire is used according to the manufacturer’s operating instructions. Cracks and blisters to the cylinder are not considered a failure of the ceramic firebox.

All other parts are warranted for 12 months from the date of purchase. This warranty does not cover damage or failure caused by tampering, carelessness, abuse or misuse, cosmetic damage or general wear and tear – this includes damaged door knobs and broken door glass. All cases will be considered at the manufacturer’s discretion.

Please note: the warranty only applies to the original owner registered on the warranty card and cannot be transferred without express permission by the manufacturer.

What are the technical specifications of the Pyroclassic IV?

Please see the last page of the Pyroclassic IV brochure, which can be downloaded HERE.

I am building a very airtight home. Do I need to install an air vent?

All wood fires need oxygen to operate effectively. The Pyroclassic IV needs 3.6 cubic metres of air per kilogram of wood. Like all wood fires, if you starve the unit of air, which can easily happen with airtight homes, it will not operate correctly and puff smoke back into the room. For these reasons, we strongly recommend you put in an air vent, approximately the size of a brick.

What are the clearances for a Pyroclassic IV installed on a Mini raised woodbin?

You can download the installation clearances for installing a Pyroclassic IV on a mini raised woodbin HERE.

What does it mean by the Pyroclassic being 'self regulating'?

The vigorous fire near the loading door automatically slows down as the burning front advances through the firebox towards the back. Each cycle ends with ash and hot ember at the far end of the firebox. Only use the Turboslide when lighting, adding fresh fuel or if you quickly want a very vigorous fire. The Pyroclassic® IV not only provides heat soon after start up but it also stores a lot of the heat from burning your wood, you will get most of this heat back over several hours. Frequent reloading may result in high room temperatures but you will soon know how much and how often to add fuel, the best heater output control is how much and how often you do this. The Pyroclassic® IV is designed to save on firewood and to keep emission levels to the minimum by storing the surplus heat which normally goes up the chimney – this heat is still being released into the room even when the fire is low at the end of each burn cycle.

How are wood fires authorised?

There are two steps a woodburner model needs to go through to be authorised:

- The emissions and efficiency of the model are tested by a laboratory. The laboratory issues a test report which states the results of the test.

- An independent body (Environment Canterbury or the Nelson City Council) physically checks the model against the test report and gives the model an authorisation number.

An alternative authorisation stream was introduced in June 2011 for models of burners that cannot be tested using the prescribed testing protocol. It enables burners to demonstrate compliance with the National Environmental Standards for Air Quality using a functionally equivalent method.

See Authorisation procedure for functionally equivalent methods [PDF, 495 KB] [Environment Canterbury’s website]

See more information at http://www.mfe.govt.nz/air/national-environmental-standards-air-quality

What dimension is the cylinder?

The cylinder of the Pyroclassic IV is 555 mm long, 367 mm outside diameter and 307 mm inside diameter.

The cylinder of the Pyroclassic Mini is 368 mm long, 367 mm outside diameter and 307 mm inside diameter.

The cylinder is 30 mm thick.

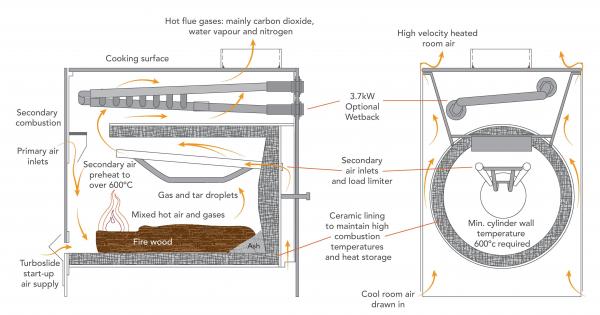

How does burning work with the Pyroclassic IV?

Solid wood must change to gas and vapour before any burning can take place. This change occurs by heating wood to high temperatures to make the best gas fuel, low temperatures will make smoke and tars that are simply unburnt fuel. The Pyroclassic® IV is a North/South burning fire so the fire is started in the front of the fire chamber and continues along the length of the wood to the rear. To make the best use of your firewood please ensure logs are placed lengthways into the fire chamber – NOT sideways. Your objective is to achieve a high temperature in the fire chamber quickly, which is easy using the Turboslide and dry wood. You will never get the fire to burn correctly if you try starting fires with green or wet wood. The only fuel authorised for use with this appliance within Urban Clean Air Sheds and Smoke Control Zones is well seasoned wood with a moisture content of 25% or less on wet weight basis, 12-18% is ideal.

Customer Help Centre

Getting Started FAQs

Click or tap a question listed below to expand for an answer.

What wood should I be using?

Short answer

DRY. This means a maximum of 25% moisture content but ideally under 18% if possible.

Do not burn any wood which has been treated as this will release poisonous gases and dioxins. Do not use any driftwood as the salt content can cause irreparable damage to the ceramic cylinder and metal components. Younger softwoods and timber which has a higher moisture content will produce a greater volume of creosote and soot than dry, well seasoned hardwood.

Logs should be approximately 100mm – 120mm in diameter by around 300mm – 400mm long for your Pyroclassic IV Fire. Logs should be approximately 100-120 mm in diameter by around 200-250mm long for your Pyroclassic Mini Fire.

Long answer

Dry wood is a must. To get the heat out of wood the fuel must pass through several stages. Firstly, free water that is not chemically bound with the wood is driven off – even wood at 20% moisture content still has to get rid of 2 litres of water for every 10 kilograms of wood. In the second stage the wood breaks down into the volatile gases, liquids and charcoal. Finally, the charcoal is also gasified, burning with a very short flame close to the char surface that appears to glow. In wood stoves all stages proceed simultaneously.

Wood is the most prolific worldwide, solar embedded, carbon sequestered energy source which is renewable in a human lifetime. It will provide energy when the sun is not shining and the wind is not blowing, when the outside temperature is above or way below freezing and when the electricity is not coming out of that little hole in the wall. If the abundant, worldwide timber resource is managed correctly it is the most sustainable, environmentally safe, renewable, resource we have and it has sustained mankind for centuries, providing us with warmth for the space we live in, warm water to clean with and the ability to cook food.

With the discovery of more energy intensive and easily transportable fossil fuels, wood was relegated to a lowly place in the order of preference and although it is bulky to transport it is the safest as it does not need a specially built pipeline, it won’t suddenly explode or cause devastating marine pollution and with almost no refining can be used in its raw state. The closer it is used to the place where it has grown makes this an even more environmentally friendly product.

Most designer wood burners catering to aesthetic demands totally disregard the thermal conductivity of wood. Microscopic examination of wood shows the channels which carry the liquid nutrients up and down the tree; consequently the properties of wood are very different along the grain than across it. Heat moves along the grain about fifteen times faster than across it, therefore, solid wood across the grain does not conduct heat and is an effective insulator meaning it does not readily burn.

When a fire is lit, even by rubbing two sticks together, the gasification process starts and it is the combustion of these gases with air that produce heat which we see as flames and smoke. When heat cannot penetrate wood easily, i.e. across the grain, the volatiles given off are not rich enough nor hot enough to burn efficiently. Efficiency apparently is not a consideration in such panoramic appliances.

This is getting to the really nerdy bit now…

Burning of the volatile gases delivers over 60% of the heat stored in the original log but few heaters can recover the major portion of this heat as the volatiles must be over 600°C and mixed with hot oxygen to burn them. Now these are difficult conditions to meet and here’s why: if the main air supply comes from under or around the burning logs, the glowing char consumes all of the oxygen – it takes only 5cms of glowing char to consume all the available oxygen. At that point, incomplete combustion continues as characterised by increased carbon monoxide and tars which mostly go up the chimney where the unburnt volatiles deposit on the flue walls as a highly flammable, gummy substance known as creosote. It is wrong to introduce cold secondary air above the fuel as it cools the gases below their ignition temperature and now they won’t burn at all. The requirement is to introduce a highly pre-heated but variable volume of air for the different stages of combustion. This is done very efficiently by the secondary air tubes inside the Pyroclassic IV fire.

All fires consume large volumes of air in order to extract the oxygen required to burn their fuel. One kilogram of wood needs 3.7m3 of air to burn completely, although this is only a theoretical minimum for stoichiometric combustion. Such ideal combustion does not exist in real life as only some of the oxygen in that amount of air can be used and therefore ‘cool fires’ need some 200% – 300% excess air to get the oxygen they need. Therefore some 7 – 10m3 of air per kilogram of wood pass through the firebox cooling the core temperature inside it and cooling air below 600°C , which kills the reaction needed to burn the volatiles. In most fires the air needs of the fire make it work against itself making it inefficient and polluting, the excess air it uses only goes up the chimney with all that gas, tar and particulates. A Pyroclassic IV only uses super-heated air in its secondary burn cycle ensuring there is no cooling of the firebox and no excess air consumed.

Burning wood scientifically is done very effectively by the Pyroclassic IV freestanding woodburning fire but even the cleanest and most efficient woodburning stove needs logs which are as dry as possible to give the best output from your fuel. Check the moisture content of your wood when you buy it and then let nature do the hard work for you. Stack it off the ground in an open sided, roofed store to allow plenty of air flow around it for as long as possible or at least until the moisture content is below 20%. It’s then ready to be used in your Pyroclassic fire to give you a nice warm house right through winter in the most efficient and cleanest way possible.

What is the best type of wood to use?

A number of things should be considered when using wood for heating. An understanding of the various types of wood fuel that is available including its advantages and limitations, and it is essential to know how to light and maintain a good fire.

Wood fuel ranges from soft woods like pine, to hardwoods like manuka. But whatever wood is chosen, the key to a successful fire is to ensure the fuel is as ‘Dry’, or as ‘Seasoned’, as possible.

Green wood can hold up to its own weight in moisture and sap and it takes time to get rid of this.

While surface water does not really matter because that will evaporate quickly, it is important to reduce the sap levels within the cell structure of the wood itself. Softwoods will season quite quickly, in about 6 to 12 months, but it can take for 18 months to 2 years for hardwoods such as Manuka to dry to an acceptable level.

Most woods make suitable fuel, pine is common and good its high resin content and loose cellular structure means it burns faster than some others, so be prepared to make more trips to the wood shed. Macarocarpa and gum are also excellent fuels although marcarocarpa tends to spit and spark more than a lot of other fuels and in some appliances this may cause servicing problems because of fly ash.

It is suggested avoiding native timber for fuel, unless it becomes available through demolition or natural attrition. Manuka though, is considered a nuisance timber in some areas of New Zealand, and could be used for fuel. It is indeed good fuel – provided it is dry – but remember, drying Manuka will take a long time.

If you knock two pieces of seemingly dry wood together if it “rings” rather than “thuds” it is likely to be dry, regular use of a moisture meter will ensure you know just how dry your wood fuel is. However simply because a piece of wood is dry on the outside, it doesn’t mean that it is dry enough to burn. Conversely, even if the outside is wet, if it is seasoned properly, it will often burn beautifully. The drier the wood, the cleaner the burn, the less likely is creosote formation and unburnt smoke being exhausted from the flue.

Place a piece of timber on a good fire base if three sides are burning within 15 minutes, the fuel can be considered to be “dry.”

How should I store my wood?

Gathering and stacking wood in the open air over the summer period is advantageous because the warmth of the sun and good air circulation will automatically evaporate some of the sap. When the wood gets wet from seasonal rain, the rain water replaces sap and because water is more quickly evaporated, the fuel dries faster.

Split larger logs, so that the largest surface area of the internal wood is exposed to the atmosphere, stack the wood loosely, on bearers, with the ends facing a prevailing wind, cover with a plastic sheet on a light frame to create a warmhouse effect, with the sides open to the prevailing breeze so it can flow freely through your stack.

Do not use it until it is fully seasoned, do not stack rotten wood – it has very little useful heat in it and leave the bark on split wood – it helps to provide natural protection from rain.

Can I burn driftwood and other treated timbers in my Pyroclassic?

You cannot burn driftwood or treated timber in your Pyroclassic. Treated timer and certain enamel and lead based paints can create a volatile environment once heated up to high temperatures. When you burn driftwood the salts become very corrosive and eat into the softer ceramics leaving behind the harder silica aggregates.

There is a lot of useful information about wood you can burn under our Useful Links section, HERE.

How do I light my first fire?

1. Soak the reusable fire starters in methylated spirits. Tip: It is also handy to store the fire-lighters in a glass jar filled with methylated spirit.

2. Slide the Turboslide to the far right or far left position. This opens the air hole inside the door and allows air to flow through acting like an old fashioned pair of bellows.

3. Place DRY kindling and a few small logs lengthways in the front of the fire chamber leaving a clear space in front of the air inlet hole.

4. Place a soaked fire starter just under the kindling at the front of the fire chamber and light it. Try to avoid dripping methylated spirit on to any surface when doing this as it can discolour some hearth materials.

5. Close the door.

6. Once the fire is burning really well and you have a nice bed of hot embers, move the Turboslide to the central position (to cover the air inlet hole), this can be done slowly in several stages if preferred.

7. When opening the door to load more wood, slide the Turboslide to the far left or right open position, and continue as in number 6.

How do I refuel the fire?

Use the rake to evenly distribute the hot ember and ash along the base of the fire box, ensuring there is sufficient hot ember at the front to provide adequate ignition to the fresh fuel load. Load the fresh fuel so the logs are loaded lengthways and one end of each log is in contact with the back wall of the firebox. If you keep your fire burning under the metal air tubes which run along the top of the cylinder, this will ensure the maximum amount of heat is captured within the ceramic cylinder. As hot gases have the most distance to travel before entering the flue, this allows the whole fire to retain as much heat as possible. When raking, avoid plugging the Turboslide inlet with char or ash (this is the hole covered externally by the Turboslide below the door). Using other tools may cause damage to the ceramic cylinder, always take care not to impact the ceramic surface.

What is the ideal operating temperature range of the fire?

There is no ‘max temp’ for a Pyroclassic, the ceramic cylinder has an operating range safe up to 1450 Celsius and the maximum temp wood fuel can burn at is 1100 Celsius in optimum conditions. The door glass will emit heat at approx. 350 Celsius and the top plate typically gets to a maximum of 550-600 Celsius during high fire burn cycles. The fire is designed to withstand and tolerate these temps over and over again with no stress to the unit, there is no welded box to fatigue under expansion in a Pyroclassic and so to answer your question no there is no maximum limit.

How do I clean the glass?

If the correct quality fuel is burnt in the right manner, the glass should stay relatively clean. The air wash which passes down the inside of the door will scrub off any deposits during the burn cycle. If the glass is becoming dirty then scrunch two pieces of damp newspaper, dip one in cold fire ashes and rub over the inside of glass, use the other to rub over the glass to clean off the dirt. Do this in the morning before rekindling the fire as the glass will be cool enough at this time. To help keep the glass clear and clean if it is becoming dirty then get into the habit of cleaning it regularly as this will maintain the glass and prevent ashes from being fused onto the glass due to intense heat in the firebox.

When and how should I clean the flue?

Pyroclassic Fires are renowned for burning very cleanly when dry fuel is used but you should still always clean your flue once a year. This is often a requirement for many insurance companies.

Keeping your flue pipes clean will help eliminate the risk of a flue fire. Your flue is also a great indication of how your wood fuel is performing. If the pipes are clean then the wood is good, if the pipes are filling up with carbon, creosote and tar deposits then you may need to revisit the operating instructions and refresh yourself with how to create a cleaner burning fire.

The easiest way to clean the flue is by placing a deep baking tray or similar under the base of the flue and sweep the flue down into this, this stops all the debris from falling into the top chamber and requiring vacuuming out. Sweeping the flue into the top chamber is never a good idea as it can restrict the flow of gasses from the primary fire chamber and cause your fire to perform poorly.

To clean the top chamber and wetback, you will need to remove the top plate (it just lifts off) and clean out the top chamber of soot and creosote. Take care not to remove any of the Kaowool lining during cleaning and ensure that the gasket is all intact before replacing the top plate. Support the flue with a frame made of wood so you can easily remove the top plate.

The build-up around the wetback is best removed by hand. The wetback can be knocked out of alignment if it is moved when the creosote is being cleaned off so be careful as this can cause the constant rise to be knocked out of alignment and can result in water hammer developing in the system.

How do I clean the outside of the Pyroclassic and the flue pipes?

The powder coated panels on the Pyroclassic can be wiped clean with some light detergent and warm water. You can choose to do this with the panels on the fire or remove them for a more thorough cleaning. Be careful when you remove the front panel to not tear the insulating gasket which is on the inside of the panel: you will need to pull the centre of the panel forward slightly to allow it to clear the space behind it when you slide it up.

The stainless steel flue pipe can be cleaned using a soft cloth with a small amount of methylated spirits soaked into it. Try to avoid touching the flue pipe with your bare hands as this leaves oils from the skin on the pipe and becomes very hard to remove once the pipes have been heat cycled.

What proportion of heat comes from the back of the fire and the flue in comparison to the front and sides?

This is a difficult question to answer. Most of the radiant heat from the fire comes from the top plate (more front than back) and the door area. The cooler convection heat comes off the extruded coloured panels around the sides and the front of the fire.

By comparison, the heat from the rear of the unit is much less than that from the other sides but it can still get to quite a temperature around that area. What that temperature is can vary depending on what the fire is doing, it is almost never a static output.

What do I do with my warranty forms?

Please make sure that both copies of your warranty paperwork have been completely filled out with all your details, the details of who you purchased the fire from, and your installer’s details for both the fire and the wetback if applicable.

WARRANTY

The ceramic firebox in the Pyroclassic IV is warranted for 15 years against defective material or workmanship, providing that the fire is used in accordance to the manufacturer’s operating instructions. Cracks and blisters to the cylinder are not considered a failure of the ceramic firebox. All other parts are warranted for 12 months from purchase. This warranty does not cover damage or failure caused by tampering, carelessness, abuse or misuse, cosmetic damage or general wear and tear, this includes damaged door knob and broken door glass. All cases will be considered at the manufacturers discretion.

Note: the warranty only applies to the original owner registered on the warranty card and cannot be transferred without express permission by the manufacturer.

Please make sure that both copies of your warranty paperwork have been completely filled out with all your details, the details of who you purchased the fire from, and your installer’s details for both the fire and the wetback if applicable.

How do I use my moisture meter?

How do I use my re-usable fire starters?

Place the soaked fire starter in the front of the fire chamber just underneath the front of your kindling. When the fire has started use tongs to remove it and place somewhere safe to cool down. When the fire starter is cold, place into a jar of methylated spirits for storage.

Warning

- NEVER leave methylated spirits near the lit fire

- NEVER soak a hot fire starter in methylated spirits

- NEVER squirt spirits or any liquid fuels directly into the fire chamber

What is a Turboslide and how do I use it?

The Turboslide is the part on the front of your fire with the Pyroclassic® name plate on it.

The purpose of the Turboslide is to cover the air inlet hole, which allows air to enter quickly when lighting a fire to get it going. To open the hole move the Turboslide to either the left or right. When your fire has caught and is going well, cover the hole with the Turboslide by putting it back into the middle position. To make sure your Turboslide is working at its peak, remember to keep the small area around the hole (i.e. the very front part of the fire chamber) free of ash or char. Simply push back the build-up a little with the rake. If the hole is clogged it will not work as it should and the fire may be hard to start. A little bit of housekeeping pays off with a quick starting, free breathing hot fire.

IMPORTANT: The Turboslide is for the initial start-up of fires and to help ignite fresh fuel if required ONLY. Once a hot fire is established, close off the Turboslide air supply hole by sliding the Turboslide to the middle position. With this method you will enjoy low emissions, high thermal efficiency and conserve your wood supply.

NOT FOLLOWING THESE INSTRUCTIONS CAN RESULT IN DAMAGE TO THE AIR TUBES AND OTHER METAL COMPONENTS INSIDE THE FIRE CHAMBER.

How do I remove the ash from my Pyroclassic?

Remove the ash when the fire chamber is relatively cool. Use the Pyroclassic curved shovel to slowly empty the fire chamber. Ash almost always contains some hot ember.

Never use a vacuum cleaner. Obtain a metal (non-combustible) ash container with a lid. Store outside on concrete or bare ground.

Pot ash can be great for your garden if your soils are acidic, use only ash from a cooled fire which used good quality wood.

How often do I need to clean out the ash?

The chamber in the Pyroclassic IV can operate with or without ash in it. However, it is preferential to empty this out every week or when the ash builds up to the extent that it could inhibit the operation of the Turboslide.

What size firewood should I be using in my Pyroclassic Fire?

Logs should be approximately 100- 120 mm in diameter by around 300mm – 400mm long for your Pyroclassic IV Fire.

Logs should be approximately 100-120 mm in diameter by around 200-250mm long for your Pyroclassic Mini Fire.

Can I use other tools in my Pyroclassic fire chamber?

Depending on how the fire is used, the surface of the cylinder can wear and erode over time. This can be accelerated through using the wrong tools, such as a flat shovel to remove ash (shown below). As you can see, this has resulted in two carved grooves in the ceramic. Although this is not ideal, it is not of a major concern as the cylinder wall is over 35mm thick so it will not compromise the integrity of the structure and the surface can easily be repaired through the application of veneering cement, which can be purchased from our Online Shop.

Customer Help Centre

Flue Questions

Click or tap a question listed below to expand for an answer.

What type of flue do you recommend?

We recommend a 150mm flue kit for your Pyroclassic Fire.

As we are a carboNZero certified organisation, we are not keen to support the unnecessary freight of bulky flue components great distances when there are comparable products available from reputable manufacturers in your locality. Please speak to your local Pyroclassic agent about the Flue Kit options available to you in your area.

What chimney sweeps can you recommend to clean the flue?

It would be great if we could keep an up to date national register of all the good chimney sweeps around the country but as you can imagine this is a somewhat transient profession and so a call through the good old yellow pages and an ask around some friends is usually the best course of action to get a sweep.

It is always worth asking them if they have done any local Pyroclassic fires before and if so can they tell you where so you can ask the homeowner how it went, any doubts and we are always happy to give some tips to proactive chimney sweeps.

What proportion of heat comes from the back of the fire and the flue in comparison to the front and sides?

This is a difficult question to answer. Most of the radiant heat from the fire comes from the top plate (more front than back) and the door area. The cooler convection heat comes off the extruded coloured panels around the sides and the front of the fire.

By comparison, the heat from the rear of the unit is much less than that from the other sides but it can still get to quite a temperature around that area. What that temperature is can vary depending on what the fire is doing, it is almost never a static output.

Why has the cowl not got a rain cap?

The Pyroclassic eco flue system and full flow vertical discharge cowl has been in use now for more than 20 years.

The cowl is designed to work with the fire in creating a good draw whilst not inhibiting the flow of the flue gases from the cowl. The design and shape of the cowl ensures that no significant amount of rain water can enter the flue system.

Many customers mistake the full flow cowl as the end of the flue pipe and often question whether something is missing from the cowl assembly when in fact this is the complete unit as it has no raincap or butterfly arrangement and is a straight pipe.

Why is smoke coming from my Pyroclassic fire into my room?

There are a few reasons why this could be happening:

- Negative pressure in the room – this can be caused by a household electric exhaust fan or severe pressure difference in a windstorm. Open a window to equalise the pressure.

- Severe down draft due to surrounding structures, hills, trees or roof layout.

- Most commonly, this is an indication your flue is blocked. Clear the obstruction and investigate the cause. Check the moisture of your wood and make sure you are burning good, dry wood. The flue pipe can block very quickly if you are burning wet or gummy wood. Make sure you are using a reliable chimney sweep as the Pyroclassic is different from other wood fires.

Download down draft troubleshooting info HERE.

How do I fix down draft?

Download our down draft troubleshooting tips HERE.

I am seeing dense smoke out of my chimney. What is wrong?

This can happen if you are burning wet wood, plastic materials, fire retardant-treated wood or high resin content.

This can also happen if the hot fire chamber is overloaded with wood treated with fire retardant. Do not use such fuel.

Burn seasoned wood ONLY, ensuring it is positioned lengthwise in the firebox.

My fire isn't going like it used to and performs like the flue is blocked even after cleaning. What do I do?

Remove the front panel by sliding it up. If there’s a white felt material (gasket), remove this and put back front panel.

Reason for removal: The gasket is present in Pyro models pre 2015. It was initially there to insulate the bolt but we found it restricted airflow as it tore and clogged the primary air intakes causing the fire to be starved of air.

If the gasket is not there and you are still experiencing these same issues then it is likely to be one of these three reasons:

1) Use of wet or unseasoned fuel – test your wood with a moisture meter by splitting a log in two and spiking the centre. If wood is above 20% this is not ideal and you should look at getting some drier wood.

2) Flue height – it could be a case of the flue not getting enough draw so it needs to be extended to create more positive draw. Every house is different, some houses require 600mm, some 1200mm. This depends on roof configuration and external factors like neighbouring buildings, trees, cliffs & wind.

3) Operation – you may be unintentionally not allowing the cylinder to get hot enough. Leave the Turboslide open for 30-45 minutes on initial start-up and open again for approximately 5-10 minutes after refuelling to ensure the new fuel has ignited and for the cylinder to maintain an optimum temperature.

My flue pipe has turned a copper colour in one section. What has happened?

If there is a concentrated spot of heat like a ring around the pipe then this is an indication of a possible internal flue fire. This is caused by a build up of creosote within the flue pipe which has then caught fire. If this is the case then a sweep would be recommended. Make sure you are using a sweep that has done a Pyroclassic fire before or has watched our video about flue cleaning. It would also pay to check the moisture content in your wood by splitting one of your logs in half and spiking it with the moisture meter that came with your Pyroclassic IV. Wood should be less than 20% to burn clean & efficiently.

Customer Help Centre

Fireplace Questions

Click or tap a question listed below to expand for an answer.

How do I find the serial number of the fire?

The serial number is printed on a metal plate at the back of the fire. To view the panel, simply slide it up to the left side and you will be able to view it from the front.

I would like to move my existing wood fire to another location within the same house?

An existing burner that is moved within a house is considered to be a newly installed burner, so it must meet the woodburner standards in the National Environmental Standards for Air Quality. You may also need a building consent.

See more information at http://www.mfe.govt.nz/air/national-environmental-standards-air-quality

Can I make modifications to my authorised woodburner?

Authorised woodburners have been designed and tested to ensure that they meet emissions and efficiency limits set out in the National Environmental Standards for Air Quality. Modifications may result in more emissions being discharged or a decrease in efficiency, which will invalidate the authorisation.

Modifying your woodburner without the advice of the manufacturer may also create a fire hazard or other safety risks.

See more information at http://www.mfe.govt.nz/air/national-environmental-standards-air-quality

What are the National Environmental Standards for Air Quality?

The National Environmental Standards for Air Quality (NES) are regulations made under the Resource Management Act 1991 which aim to set a guaranteed minimum level of health protection for all New Zealanders.

The NES came into effect on 8 October 2004. They are made up of 14 separate but interlinked standards.

These include:

- Seven standards banning activities that discharge significant quantities of dioxins and other toxics into the air

- Five standards for ambient (outdoor) air quality

- A design standard for new wood burners installed in urban areas

- A requirement for landfills over 1 million tonnes of refuse to collect greenhouse gas emissions

More information about the 2 hectare rule the NES

Most urban areas in New Zealand experience air pollution during winter. Our focus is on improving air quality in those areas. Urban areas typically have smaller property sizes and as there is no nationally consistent definition for an urban environment, a property size of less than 2 hectares was used. The standard two hectare rule applies throughout New Zealand including rural areas.

See more information at http://www.mfe.govt.nz/air/national-environmental-standards-air-quality

Why is the Pyroclassic sometimes shown as having a 4kW heat output and sometimes 15kW?

The 4kW rating for the Pyroclassic IV comes from the efficiency and emissions testing procedure. This heat output test is a byproduct of other tests and it is acknowledged throughout the industry that this method of testing disadvantages fires with a higher thermal mass.

In light of this the New Zealand Home Heating Association (NZHHA) established a standalone testing procedure specifically designed to measure the actual kW output of a fire in the laboratory environment. The Pyroclassic IV is only one of a few fires to have been tested with this procedure and the results have confirmed the Pyroclassic IV is capable of providing a genuine 15kW of heat for your home.

A more accurate way of measuring how well a wood burner will heat you home in the real world is to look at the space heating rating which is usually shown in m2. The higher the area shown the better the fire will be to heat the whole home. The Pyroclassic IV is rated up to 250m2, which is one of the highest ratings of any domestic wood fire.

What is a load limiter?

Along the top of the fire chamber is a load limiter, which is designed to restrict the operator from overloading it. This will burn off in approximately 3-7 years depending on frequency of use. The load limiter does not need replacing but the airtubes will.

What are the secondary air tubes?

The replacement secondary air tubes are designed to slip over the burnt down tips of the existing air tubes which are welded into the back plate of the fire, these existing tubes need to be cut down to approx. 70mm long from the face of the rear ceramic or 100mm long from the steel back plate surface behind the ceramic, this should allow the replacement air tubes to slide in and over the short piece of tube left, we recommend applying a small amount of fire cement on the end of the original stump to seal and secure the new tubes on. If the original air tubes are too long then these will need to be cut down to suit.

Do you recommend using Smartburn in the Pyroclassic?

We have not carried out any testing with the SmartBurn in the Pyroclassic so we have no official data to go from and based on the limited knowledge we have of it there is little to suggest that it would make any significant difference to the burn environment inside a Pyroclassic.

A Pyroclassic in good working condition should not need a SmartBurn or similar in it to achieve a good, clean, effective and efficient burn.

How can I test if I am getting good heat output from my Pyroclassic fire?

As you will note in the operating instructions for the Pyroclassic IV, the fire will not give its full performance for the first few uses until the unit has fully cured and heat tempered.

A couple of quick checks to measure the approximate output levels is to hold your hand 10cm off the centre of the top plate when the fire is running. If you can’t keep it there for 5 seconds then the fire is cranking along. If you can between 5 – 10 seconds then the unit is performing well in its expected typical output range. If you can hold it there for more than 10 seconds then you can probably hold it there indefinitely and so depending on the heat required you could load a fresh fuel charge in and begin the cycle again.

The side panels are also a good indicator of when a Pyroclassic is fully heat cycled. If the bottom back corner of the side panel is warmer than skin temp then the whole cylinder is hot, if it’s not warmer than your hand then it is still warming up.

Can I put a natural tile on the wall instead of the wall screens? Does this comply with the 'non combustible wall' requirements?

Any non-combustible mineral board that is directly fixed to a combustible material like timber immediately loses its non-combustible qualities and therefore the full clearances must be applied. If this board were to be packed 25mm off the combustible material underneath and then ventilated top and bottom with 25mm air gaps then this would become a non-combustible wall covering. This can be covered with any other non-combustible material you like such as tiles etc.

As a note of caution please be aware that Fireline Gib is not a non-combustible wall covering.

What are the ceramic chips/divots in my cylinder? Is it normal?

These are exposed air blisters and are completely normal. The blisters are a result of small air pockets getting trapped just at the edge of the surface in our castings. Depending on how much air is trapped inside these, they sometimes erupt and take a piece of the ceramic off. These will not affect the performance of the fire at all.

There is over 35mm of thickness to the cylinder, and this is then wrapped in a thick insulating blanket and a complete steel band to ensure that nothing can escape from the cylinder walls.

Example:

My fire is slow to start up. What can I do?

- Open the Turboslide by moving it to the far left or right position.

- Check the start-up hole is free of ash and char on the inside, push back any build-up with the rake. The start-up air supply hole allows air to enter the fire chamber like a pair of old fashioned bellows, if the hole is clogged with ash and char it will not work.

- Check for air leakage around the cook top, around the flue collar and in the flue pipe joints. Air bypassing the fire chamber reduces draft. Repair any air leaks.

- Slow start up can occur if you are fueling the fire with large or wet logs or loading onto too few hot coals. Use dry kindling to start fire quickly. DO NOT USE WET FUEL.

- Insufficient draft. Review chimney construction and investigate air pressure levels in the home.

- Warm, humid conditions outside or an inversion layer. Wait until the flue pipe heats-up.

Do I need to grease the doorknob spindle?

A small amount of graphite grease should be applied sparingly and only occasionally to the spindle of the doorknob, twice a year is usually sufficient.

Ashes from the fire have a gritty texture and over time this can cause wear on the doorknob spindle. Use a tiny amount of grease to lubricate the groove in the first thread of the spindle which can be applied with a matchstick or cocktail stick.

Please note: only a small amount is needed, if too much is used it will melt and dribble down causing an unsightly stain, be sure to remove any excess before relighting the unit.

My powdercoating looks worn after cooking?

The top plate of the Pyroclassic is 10mm plate steel which sits directly above the heat of the firebox making it a great surface for cooking on if desired, however as with all cookers, if used, this will leave some evidence of cooking so this is normal to show signs of use. This impact can be reduce with careful choice of how to cook and in what pan or pot, so for baking and roasting fully enclosed containers are ideal, if you are going to be frying and sautéing then this will obviously create more deposits. A good way to minimise the clean-up is to use a large piece of aluminium foil across the top which will stop any spills from marking the fire. The top plate is painted in a special Senotherm paint which can withstand very high temperatures, this allows it to be able to ‘burn off’ most spills and marks, however the powdercoated panels are not heated to the same level and so would not be able to self-clean like the top plate, these panels are therefore powdercoated to allow a smarter look in a wide range of colours.

Why is my fire chamber rusty?

Iron oxidisation or rust is due to elevated moisture levels, this can occur for a number of reasons but the most common cause is from water ingress via the flue system. The extent of the rusting on the cylinder is not sufficient for it to cause any issue if it is stopped now, so the cylinder should be wire brushed off and treated with some rust stopper and then painted with some zinc galv type aerosol product if possible.

To ensure this is stopped from recurring an investigation into the cause of the water ingress should be conducted, it is usually either through the cowl and top casing assembly or through the flashing detail, if there is no evidence of any water ingress on the ceiling tile area or the outside of the flue pipes then it would suggest the top casing area.

Due to the result of climate change and the increased occurrence of high rainfall events in NZ we have recently introduced an all-weather butterfly that can be inserted into the cowl to help assist in reducing the effects of these very high rainfall events, this is available on our website under part P843.

Why are cracks and deterioration in my Pyroclassic cylinder?

This is a natural way to relieve built-up stress in refractories. It has no effect on operation, performance or useful life of the unit. The firebox is an arch structure, the most stable and permanent construction known. These cracks will develop over time and is nothing to worry about.

Due to it being cast as a one piece cylinder it goes through some expansion and contraction every time it is heat cycled. This is just the cylinder relieving its inert tension and results in a variety of different levels of cracking.

These cracks and blisters can slowly grow over time due to erosion through use. If you do not like the appearance of the cylinder when cracks appear, you can purchase veneering cement which can be mixed to a toothpaste like consistency and inserted into the cracked areas.

The story goes that the two original designers each had a Pyro and one touched up his cylinder every year and the other never touched his…25 years later both fires were still working albeit one was looked in better looking condition internally than the other!

25 year-old Pyroclassic II Cylinder

Why is smoke coming from my Pyroclassic fire into my room?

There are a few reasons why this could be happening:

- Negative pressure in the room – this can be caused by a household electric exhaust fan or severe pressure difference in a windstorm. Open a window to equalise the pressure.

- Severe down draft due to surrounding structures, hills, trees or roof layout.

- Most commonly, this is an indication your flue is blocked. Clear the obstruction and investigate the cause. Check the moisture of your wood and make sure you are burning good, dry wood. The flue pipe can block very quickly if you are burning wet or gummy wood. Make sure you are using a reliable chimney sweep as the Pyroclassic is different from other wood fires.

Download down draft troubleshooting info HERE.

Air supply

The room or space containing the Pyroclassic needs no additional ventilation unless a draught stabilizer is fitted, in which case a permanent opening of at least 1500mm2 should be provided. Any air opening must be kept clear from blockage and obstruction. Due consideration should be given to air requirements for any other appliances in the same room or home, such as heat transfer kits, kitchen range hoods, laundry dryers, bathroom vents etc.

If your fire has been installed into a new build home, these are constructed to be far more air tight than older housing can have an significant impact on the free air available over time to the fire, especially when other forms of mechanical extraction from within the home are used such as range hoods, dryers, wet room extraction etc. In severe cases the flue pipe can actually end up being used as the means of ventilation causing the flue gases to then be drawn into the house. This is not a fault of the fire but a flaw in the inadequate ventilation planning of the house construction and NZ building code.

A further point of note on the house topic is the location of the house in relation to its surroundings and the termination of the flue system, this is often referred to as downdraft.

Door knob troubleshooting

The expected lifespan of a door knob is somewhere between 4 – 10 years depending on how the fire is being operated.

The door handle will get hot during operation and this is completely normal.

There are two typical known causes of premature failure of the door knob. The first is excessive charring on the back of the knob due to high levels of concentrated heat from burning close behind the door area. The second cause can be due to the door being over-tightened when it is closed which in turn leads to it being very tight to open once the fire has heated up. The continued cycle of this over-tightening causes the screws to become weakened from the higher levels of load put on them in each direction each time, which eventually results in it coming loose and breaking away from their fixings.

A combination of these two is actually the most common cause of door knob failure. To avoid these issues and extend the lifespan of the door knob, keep a clear area of approximately 10cm in the front of the firebox and maintain your fire underneath the air tubes in the top of the cylinder, this will give the additional benefit of letting the cylinder absorb the maximum amount of heat from your fuel load before it leaves the fire chamber.

If you are finding the door knob too hot when trying to refuel your fire then you are probably trying to refuel too soon, the door knob is a great indicator of what’s happening within your fire so if you can’t reload then you don’t need to yet. If your door knob is starting to show signs of charring then you are probably burning your fire too close to the door.

Do not lean on the door or use it to help you stand up when it is open as this can cause the door to move. If your door does become misaligned then you will need to loosen the top bolt going horizontally through the hinge bar and lift the door back into the correct position for the spindle to line up and then re-tighten the bolt.

Why is there pale blue smoke early in the morning?

The Pyroclassic is burning off small creosote deposits formed by premature banking of the fire the night before.

Why are gases and smoke entering the room when the door is opened?

The most likely reason for this is that your flue is clogged and may require sweeping.

Other possible causes:

- You could have a very cold flue temperature. Allow initial start up fire to warm flue pipes.

- Loading door opened during maximum degassing of fuel. Wait until flames disappear.

Why is my Pyroclassic using more wood than I thought it would?

This could be because the loading door is not airtight. Check the gasket – if you need a replacement, you can purchase one from our Parts Shop.

Another common cause of this is incorrect operation. Remember the Pyroclassic IV’s significant heat storage capacity. Add logs less often and burn fuel further back in the fire chamber.

Lastly, this can happen if the Turboslide is being left open for long periods. If this is the case, go to our Resources Page and download our operating instructions and read about how to use it correctly.

Why is my door knob charred?

This will naturally happen slowly over years of use. However, this process can be accelerated by burning with the Turboslide open continuously and having the fire right up the front near the door. Please read our operating instructions again so you can use the Pyroclassic® IV correctly.

If you need a replacement doorknob, you can purchase one from our Parts Shop.

Why is our water heating pulsating and noisy?

This is most likely an improperly constructed water-heating circuit. Make sure you re-check the layout.

Please re-read your copy of the wetback instructions, available in our Downloads tab.

Why is the door lock hard to operate?

Apply a small amount of high temperature grease to the thread (grease with graphite or molybdenum disulphide only).

This could be because you are over tightening the door spindle thread. The Pyroclassic IV door seals with minimum pressure. Do not over-tighten as this shortens the life of the door handle gasket life.

My Pyroclassic door gasket has moved out of place. What do I do?

The door to glass sealing gasket can occasionally walk along the back of the door. This happens due to the screws not quite holding enough tension on the door glass and so during the expansion and contraction process the gasket gets moved along a fraction each time.

This can be realigned by loosening the screws off and shifting it back into position so long as it’s not to stretched out. If it is damaged or stretched then it is easier to buy a new one and start again making sure to check the screw tension after a few weeks to adjust them back up to tension again. This gasket can be purchased from our Online Shop.

Our Pyroclassic fire appears to have 'rust-like' dust coming out at the bottom. What is this?

The rust dust is probably just the exposed bottom edges of the top valley walls where they meet the cylinder rap rusting a little bit due to moisture passing through the fire from the wood fuel. This is where it tends to collect and is quite normal to see and is nothing to be concerned about.

The front of my Pyroclassic fire has developed smoke stains on the panel. What can I do?

Depending on how extensive the marking is you may be able to remove it by using a light abrasive car polish. Remove the panel and place it on a kitchen bench as this will be much easier than doing it on the fire. Please be careful of the gasket if it’s still attached to the back of the front panel when removing and replacing it. Please avoid handling the panel when hot. Always make sure the panel is cold.

What can I do if my wetback develops a thick coating on it?

The wetback can develop a coating of crusty creosote when the wood fuel is not being burnt in the most efficient way. Firewood can play a major role in the performance of a wood fire. The species is part of the picture but the most significant thing is that whatever the type of wood it must be well seasoned and dry. Best performance cannot be achieved without the best fuel.

So back to the question…

Burning wood at low temperature causes incomplete combustion of the oils in the wood, which are off-gassed as volatiles in the smoke. As the smoke rises through the chimney it cools, causing water, carbon, and volatiles to condense on the interior surfaces of the chimney flue. The black oily residue that builds up is referred to as creosote, which is similar in composition to the commercial products by the same name, but with a higher content of carbon black. Over the course of a season, creosote deposits can become several inches thick. This creates a compounding problem, because the creosote deposits reduce the draft (airflow through the flue) which increases the probability the wood fire is not getting enough air to burn at high temperature. Since creosote is highly combustible, a thick accumulation creates a fire hazard. If a hot fire is built in the stove or fireplace and the air control left wide open, this may allow hot oxygen into the chimney where it comes in contact with the creosote which then ignites—causing a flue fire.

The easiest way to clean the flue is by placing a deep baking tray or similar under the base of the flue and sweep the flue down into this. This stops all the debris from falling into the top chamber and requiring vacuuming out. The build-up around the wetback is best removed by hand and the rest can be carefully removed by a vacuum cleaner.

The wetback can be knocked out of alignment if it is moved when the creosote is being cleaned off. This can cause the constant rise to be knocked out of alignment and can result in water hammer developing in the system so be careful. The wetback can develop a coating of crusty creosote when the wood fuel is not being burnt in the most efficient way. Firewood can play a major role in the performance of a wood fire. The species is part of the picture but the most significant thing is that whatever the type of wood it must be well seasoned and dry. Best performance cannot be achieved without the best fuel.

Why is my fire chamber rusty?

Iron oxidisation or rust is due to elevated moisture levels, this can occur for a number of reasons but the most common cause is from water ingress via the flue system. The extent of the rusting on the cylinder is not sufficient for it to cause any issue if it is stopped now, so the cylinder should be wire brushed off and treated with some rust stopper and then painted with some zinc galv type aerosol product if possible.

To ensure this is stopped from recurring an investigation into the cause of the water ingress should be conducted, it is usually either through the cowl and top casing assembly or through the flashing detail, if there is no evidence of any water ingress on the ceiling tile area or the outside of the flue pipes then it would suggest the top casing area.

Due to the result of climate change and the increased occurrence of high rainfall events in NZ we have recently introduced an all-weather butterfly that can be inserted into the cowl to help assist in reducing the effects of these very high rainfall events, this is available on our website under part P843.

The Pyro Fires Range

Ultra Low Emissions and Super Economic

Pyro Classic

The Classic. Suitable for most homes.

Pyro Mini

The Mini. Suitable for smaller homes.